(1446 products available)

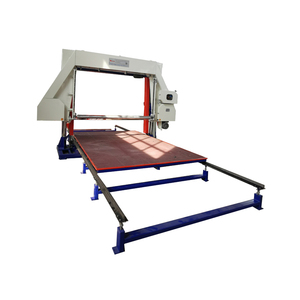

Building a foam cutter is a great project for anyone looking to work with this versatile material. A diy hot wire foam cutter table can be used to create intricate shapes and designs for various applications, including architectural models, DIY crafts, and theatrical props. The process for building a foam cutter is relatively straightforward and can be customized based on individual preferences and specific project requirements.

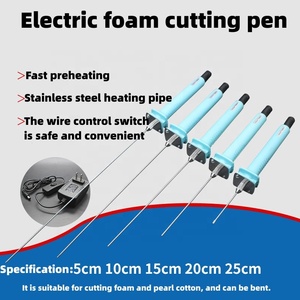

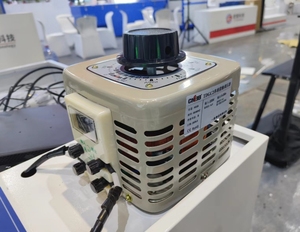

The first step in building a hot wire foam cutter is gathering all the necessary materials and tools. The key components required to build a hot wire foam cutter include a power supply, nichrome wire, a power switch, a temperature control unit, and a sturdy frame to hold the wire. Additionally, safety equipment such as heat-resistant gloves and eye protection should be used when working with the cutter to prevent any accidents. The size and scale of the foam cutter can be customized based on the specific needs of the user, whether they are a hobbyist or a professional craftsman.

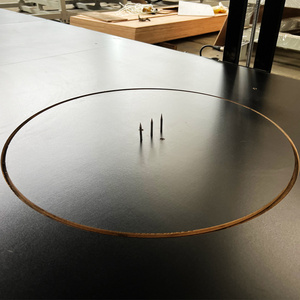

Step one is to create a sturdy frame to hold the nichrome wire. This can be done using materials such as wood, metal, or PVC pipe. The frame should be designed to accommodate the size of the foam being cut and provide a stable base for the wire. Step two is to install the power supply, power switch, and temperature control unit. The power supply provides the electricity needed to heat the wire, while the power switch allows the user to turn the cutter on and off. The temperature control unit is used to adjust the heat of the wire, ensuring precise and consistent cuts.

Step three is to attach the nichrome wire to the frame. The wire should be stretched taut and secured at both ends to ensure it remains straight during operation. Step four is to test the cutter to ensure it is functioning properly. This can be done by turning on the power supply and adjusting the temperature control unit. If the wire heats up and glows red, the cutter is ready to use. Step five is to use the hot wire foam cutter to create precise cuts in foam. The wire should be moved slowly and steadily through the material to achieve clean and accurate results.

When building a hot wire foam cutter, safety should be a top priority. It is essential to wear protective gear, such as heat-resistant gloves and eye protection, to prevent burns and injuries. Additionally, the cutter should be used in a well-ventilated area to avoid inhaling any fumes produced during the cutting process. It is also important to follow the manufacturer's instructions for the power supply and temperature control unit to prevent overheating and electrical hazards. By taking these precautions, users can build and operate a hot wire foam cutter safely and effectively.