Introduction to BT30 Spindles

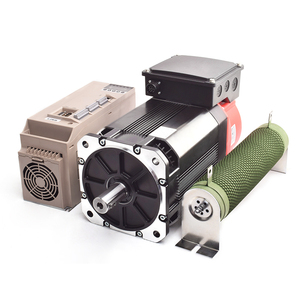

The BT30 spindle is a critical component in the realm of machining, representing a category of tool holding that is integral to CNC operations. This type of spindle is designed to interface with BT30 tool holders, which are commonly used in milling, drilling, and tapping applications. The BT30 designation refers to the spindle's taper size, which is essential for precision and stability during high-speed machining processes.

Types and Applications

There are various types of BT30 spindles, each tailored to specific applications. These include high-speed spindles for detailed engraving and heavy-duty options for robust milling tasks. The adaptability of the BT30 spindle allows for its use in diverse industries, from aerospace engineering to automotive manufacturing, where precision tooling is paramount.

Features and Materials

A BT30 spindle is characterized by its precise construction and the use of durable materials such as hardened alloy steel. This ensures minimal wear and tear even under rigorous use. The spindles often feature advanced bearing technology to enhance performance and longevity. Additionally, the balanced design of a BT30 spindle contributes to improved surface finishes by minimizing vibrations during operation.

Advantages of BT30 Spindles

The advantages of utilizing a BT30 spindle in machinery are manifold. The spindle's compatibility with a wide range of tool holders increases its versatility. Its design promotes ease of tool change, which is critical for efficient workflow. Moreover, the structural integrity of BT30 spindles ensures consistent performance, which is crucial for maintaining the precision of machined components.

Maintenance and Durability

Maintenance of a BT30 spindle is straightforward due to its simple yet robust design. The spindles are engineered to withstand the demands of continuous industrial use, resisting common adversities such as thermal distortion and mechanical impacts. This resilience translates to a reliable performance over an extended period, making the BT30 spindle a dependable choice for professionals in the machining sector.

Choosing the Right BT30 Spindle

Selecting the appropriate BT30 spindle is crucial for meeting the specific needs of your machinery. Factors to consider include the spindle's speed capabilities, torque, and compatibility with existing equipment. While Alibaba.com does not endorse or guarantee specific products, the platform offers a comprehensive selection of BT30 spindles, allowing buyers to compare and find the most suitable options for their machinery requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4