In the ever-evolving field of welding technology, the inverter welder has emerged as a game-changer, revolutionizing how welding processes are carried out. The ability to handle various welding processes, the portability of compact designs, and the precision achieved through inverter technology make these welders indispensable tools in modern welding applications. As the welding landscape continues to evolve, the inverter welder is a testament to the industry's commitment to innovation and improvement.

Applications and types of inverter welders

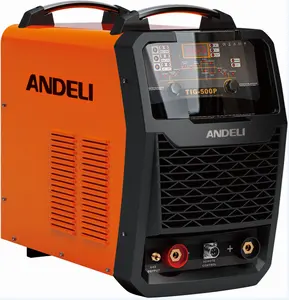

At its core, an inverter welder utilizes inverter technology to convert AC into DC, enabling a more precise and controlled welding process. This departure from traditional transformer-based welding machines has many advantages, making inverter welders increasingly popular in various industrial and DIY applications. The versatility of an inverter welder is evident in its ability to handle different welding processes. An inverter welding machine is not limited to a single welding technique. Still, it can seamlessly transition between functions such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and Stick welding. This adaptability allows welders to choose a suitable method for the specific task, making the inverter welding machine a versatile and cost-effective investment.

One of the specific applications of an inverter welder is found in the inverter stick welder. This portable and compact welding solution offers the convenience of stick welding, a method known for its simplicity and effectiveness. The inverter stick welder stands out for its lightweight design, making it a preferred choice for welders needing mobility and flexibility. The inverter technology incorporated in this equipment ensures a stable and smooth welding arc, even when working with challenging materials. The inverter arc welder represents another facet of this technology, emphasizing precision and control. The ability to adjust welding parameters with greater accuracy allows welders to achieve optimal results, especially when working on materials of varying thicknesses. The inverter arc welder is known for its energy efficiency and capacity to deliver consistent welding performance, contributing to improved weld quality and reduced spatter.

Advantages of an inverter welder

Comparing transformer vs inverter welder brings to light the distinct advantages of the latter. Traditional transformer-based welding machines are characterized by size, weight, and limited adaptability. In contrast, the inverter welder's compact size and reduced weight make it more portable and suitable for diverse working environments. The efficiency of inverter technology also translates into energy savings, as these welders consume less power while delivering superior performance.

The inverter welding machine's ability to produce a stable arc at lower amperages is a notable advantage, especially when working on thin materials. This precision and control contribute to minimizing the risk of burn-through or distortion, allowing welders to achieve more intricate and refined welds. The improved arc stability also enhances the welding experience, making it easier for seasoned professionals and novice welders to produce premium results. The advancements in inverter technology have not only impacted performance but have also improved the user experience. Inverter welders often feature user-friendly interfaces with digital displays, allowing welders to monitor and adjust welding parameters more easily. This digital interface enhances the precision and repeatability of welding processes, empowering users to achieve consistent results across different projects.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4