Pvc Cable Trunking Waterproof Indoor Floor PVC Cable Trunking Plastic Floor Covering

Pvc Wiring Ducts Curved Profiles Plastic Building Materials Factory Directly Provide Pvc Cable Trunking New Style

Pvc Cable Trunking High Quality China Manufacturer Durable Electric Pvc Wire Cable Trunking Cable Tidy

Fire Retardant PVC Cable Trunking 39x19mm Grey Wiring Ducts Solid

Pvc Floor Trunking Electrical Cord Management Pvc Arc Floor Cable Trunking Duct Pvcfor Home And Office

Cable Zipper FSCAT New Type Sprial Wrapping Band Cable Organizer Cable Zipper Cable Tidy Spiral Wrap

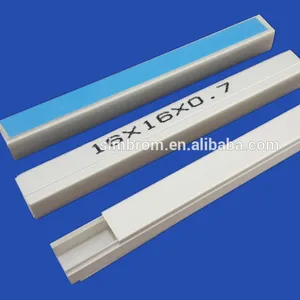

Different Size Fire-Proof 16X16 25X16 40X25 50X50 Plastic Electrical Wiring Cable Ducts Pvc Cable Trunking

Fire Resistant 10X10 16X16 16X25 40x25 Full Size Electrical White Plastic PVC Cable duct and Trunking

BESCA Waterproof Wiring Duct Resistance PVC Wire Trunking Aluminium Cable Trunking

Good Insulation Solid Through 300*100mm 200*100mm PVC Decorative Cable Trunking For Safety Using

PVC Cable Trunking Slotted Hot Sale Slotted PVC Cable Trunk Wiring Ducting 100mm Trunking

Environmental PVC Slotted Wiring Duct Plastic Cable Trunking

WBO Cable Slotted Wire Pvc Trunking 20*20 Wiring Duct 2m

(High Quality) Wire Accessories PVC Wire Cable Trunking, Decoration Wiring Duct

Best selling pvc extrusion cable trunking for wall

Hot Quality Sale Slotted PVC Cable Trunk Wiring Ducting 100mm Trunking

PVC Ducts Plastic Electrical Tray Decorative Pvc Network Wiring Cable Duct Trunking

Wholesale Factory Price PVC Cable Trunking For Protecting Wires

Wire Cover Protector Raceway Pvc Half Round Electrical Wire Cable Duct Channel, Cable Channel pvc trunking

Electrical Custom Plastic Wiring Duct Channel Raceway Tray Systems Pvc Cable Trunking

40*25mm grey color electrical slotted plastic PVC cable trunking

Electric Conduit Pvc Wire Cable Ducts Trunking And Fittings For Electric Engineering

Yobest Customize Extruded PVC Duct Yellow Plastic Fiber Optical Cable Tray Equipment Cable Trunking

PVC Cable Trunking 15X10 Mm 2 Cable Trunking Systems,solid PVC UL94, V0 M1 0,5-1 Joule CT0015010 2 Meters EN 50085-2-1 Accept TR

2020 Hot Item Electrical Wall Mounted Cable Wire Electrical Plastic PVC Trunking

40*40mm slotted pvc wire duct flexible cable trunking

Different ColorS factory supply PVC Trunking cable channel 16X16 with sticker PVC Adhesive Trunking

15*10MM 25*25MM PVC Cable Trunking with different sizes PL

CE ROHS Certificate PVC Arc cable tray floor trunking

Extra Thick 200*100mm Electric Pvc Cable Channel Cable Raceway Cable Trunking Wring Duct

White PVC Plastic Enclosed Slot Cable Tray/Cable Duct Trunking

Factory high-quality customized curved PVC trunk cable invisible anti-stepping semicircular trunking

2M 25*16Amm White PVC Good Insulation The Round Type Solid Wring Duct, 0.75mm/1.3mm thickness Cable trunking

High Quality Pvc Plastic Wire Cover Cable Trunking Duct Cable Floor Trunking Arc Floor Trunking

LESSO customizable corrosion resistance fire retardant white square plastics pvc cable trunking 100 150 50x25mm

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4