(2566 products available)

Compressor air hose fittings are essential components that connect and seal the interface between a hose and an attachment, like a tool or a pipe, while transferring air. These fittings come in different shapes and sizes for specific applications. The most common ones are detailed below.

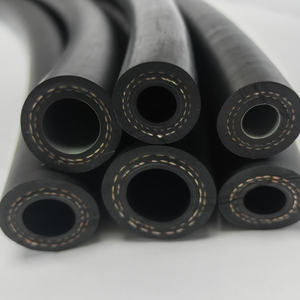

These are usually small-diameter hoses, often under an inch wide, with a flexible rubber or metal interior and exterior, mostly used in machinery and auto repairs. The fittings allow it to connect the hose to the grease source and the area it needs to lubricate. It makes tight seals between parts to stop leaks when grease goes through. The small hose means it can easily reach tiny spaces within tools or car parts while handling the thick grease without clogging up.

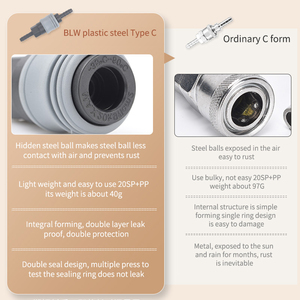

Also known as quick-release fittings or snap-on fittings, are designed for making fast and tool-free connections and disconnections of air hoses. The main components of quick-connect fittings include the male plug, which has ball locking mechanisms, and the female socket or coupler, which has grooves for the balls to fit into.

During connection, the male plug is pushed into the female socket, compressing the balls. The balls then lock into the grooves, creating a tight, leak-proof seal. To disconnect, the plug releases a simple trigger or button removes the lock, allowing for quick exchanges of hoses or tools with one hand.

Brass hose fittings are parts that connect a hose to something else, like a tool or a pipe. These fittings are typically made from an alloy of copper and zinc called brass. The alloy's corrosion resistance, strength, and easy shaping make it ideal for waterproof sealing in various industries. Since brass doesn't rust like iron, it is well-suited for areas with moisture or chemicals.

Hose end fittings are special connectors that attach to the ends of an air or fluid hose. They typically have one end that screws into the hose tightly, like a clamp, and the other end shaped differently for connecting to other parts. The different shapes can be a straight line, angled bend, or swivel to allow movement. One common type is a barbed fitting with tiny ridges that holds the hose securely on the end. These fittings create tight, leak-proof seals between hoses and other equipment.

Tyre inflator fittings are the small parts connected to air hoses for car tyre pumps. A pressure gauge measures how much air is in a tyre. A valve core remover installs or removes the tyre valve core. The inflator has a lever that the user pressers to release air from the hose into the tyre and an air chuck that grabs onto the tyre valve firmly. A quick-connect fitting connects the hose to tools and makes it easy to swap between different inflator tools.

Industrial applications refer to compressed air systems used for manufacturing, construction, and other heavy-duty jobs. They tend to have many tools, like spray guns and impact wrenches, that need air. A few common industrial applications include:

The automotive industry heavily relies on pneumatic tools powered by compressor air hose fittings. Wrenches, sanders, and paints and tyre changers use these hoses. They make repairs and building cars faster and better. The hoses are designed to withstand tough shop conditions like heat and humidity and work with different tools. Properly maintaining the hoses keeps cars fixed and new ones built. Quality parts make everything run smoothly in this busy, noisy, and fast space.

The manufacturing industry frequently employs pneumatic tools and equipment to enhance productivity, especially in assembly lines, painting, welding, and more. Compressed air is vital for moving materials, controlling machinery, and using tools like drills and riveters. Fittings, hoses, and couplers enable these diverse applications by ensuring a consistent and dependable air supply for optimal performance. Proper management of air quality and pressure is crucial to attaining the accuracy and efficiency required in manufacturing processes.

The construction industry relies on compressor air hose fittings to operate pneumatic tools such as nail guns, jackhammers, and air compressors, making tasks like drilling and fastening quicker. Construction areas have rough conditions like dirt, water, extreme weather, and heavy work. Fittings are tough and weatherproof for these conditions. Regular checking ensures they run well for building safely and on time.

The food and beverage processing industry employs pneumatic systems to handle tasks like sorting, packaging, and transporting food products, while maintaining hygiene using non-metallic fittings. Examples include filling bottles and cans, moving bulk materials like grains and vegetables with vacuum pick-up tools, and mechanizing bottle capping. In this highly regulated industry, air hose fittings help automate many processes while complying with safety and sanitation standards.

The agricultural space also uses compressor air hose fittings for tasks like running tools, maintaining equipment, and applying pesticides or fertilizers through pneumatic sprayers. That makes farming faster and cheaper. Conditions on farms can be rough, plus there is dust, mud, and unpredictable weather. So, parts need to be tough to handle these conditions.

A1. Brass, stainless steel, and aluminum alloy are among the strongest materials suitable for making compressor air hose fittings. These metals form lightweight but very tough fittings. They resist rust and wear, keeping the hoses securely attached in the harsh environments of factories, construction, and automotive service.

A2. Over time, corrosion, wear, and tear, and pressure changes cause fittings to fail. Debris inside can corrode metals. Repeatedly tightening tools can wear threads. Extreme temps contracting and expanding metal gradually weak down fittings. Breaking seals lets air escape, and leaks develop. Regular checks catch problems early so space can replace them before they break down completely.

A3. Technicians carefully install fittings onto hoses using a few methods. Some use a special tool called a "crimping" machine, which tightly compresses a metal collar around the hose and fitting to hold them together securely. Others use adhesive or solder to connect in permanent ways. Heat expansion fits a fitting into the hose end that cools to lock it in place. These methods create a strong, sealed bond between hose and fitting.

A4. The ideal hose fitting size really depends on the specific job or task at hand. For smaller, home-level tasks like inflating car or bike tires, a fitting with a diameter of 1/4 inch works well. Jobs that require more power or big industrial work usually need a 1/2 inch fitting. It's important to match the right size fitting to the hose and tool or equipment to make sure everything gets the correct amount of air pressure. This helps everything to work smoothly without any waste or problems occurring due to the wrong fitting size.

A5. Brass, stainless steel, and aluminum alloy are among the strongest materials suitable for making compressor air hose fittings. These metals form lightweight but very tough fittings. They resist rust and wear, keeping the hoses securely attached in the harsh environments of factories, construction, and automotive service.