Fabric Hole Punch Machine: An Overview

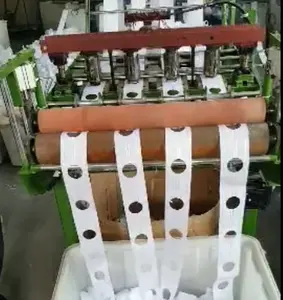

The fabric hole punch machine stands as a pivotal tool in the textile and garment manufacturing industry. This equipment is engineered to create precise holes in a variety of fabric materials, serving an essential function in the production of items such as apparel, curtains, and other textile products.

Types and Applications

Diverse in its forms, the eyelet punching machine category encompasses several types tailored to specific applications. The manual curtain eyelet punching machine is a popular choice for smaller operations or on-site adjustments, offering simplicity and ease of use. For larger scale production, automated hole punch machine for fabric options are available, enhancing efficiency and consistency in high-volume environments. These machines are not limited to textiles alone but are also adept at handling materials like leather and paper, making them versatile tools in various crafting scenarios.

Features and Materials

A fabric hole punch machine is typically constructed from robust materials such as hardened steel or industrial-grade aluminum, ensuring durability and longevity. Advanced models may include features like servo drives for enhanced precision, particularly in the eyelet punch machine for curtains, where accuracy is paramount. The adaptability of these machines allows for the processing of different fabric thicknesses and types, from delicate silks to heavy-duty canvas.

Advantages of Modern Punching Machines

Modern punching machines offer a multitude of advantages. Efficiency is significantly improved thanks to the automation capabilities of CNC-controlled units, which can be programmed for intricate punching tasks. The cloth hole punching machine variants are designed to minimize fabric waste and optimize production workflows. Additionally, the integration of pneumatic or hydraulic systems in certain models reduces manual labor and enhances the precision of the punching process.

Selecting the Right Machine

Choosing the appropriate fabric hole punch machine requires consideration of the specific needs of a project or production line. Factors such as material type, production volume, and space constraints will influence the selection process. For specialized tasks, such as adding eyelets to draperies, a curtain eyelet punch is specifically designed to handle the job with finesse. The platform's extensive catalog presents a range of machines, from portable units for fieldwork to stationary machines for continuous mass production.

Integration with Industry Needs

The integration of a eyelet hole punch machine into an industrial setting can streamline production and increase the quality of the finished product. Whether the task at hand involves creating functional components, decorative elements, or essential textile products, the right punching machine is a critical asset. With a focus on precision and adaptability, these machines meet the dynamic demands of the textile industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4