(1827 products available)

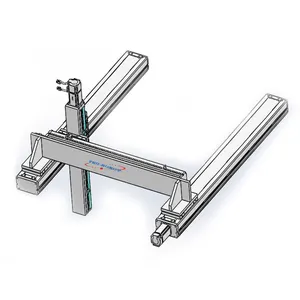

The 3 axis stage is a crucial component in machinery and automation systems, allowing precise movement in three dimensions. It is widely used in industries such as manufacturing, research, and development for applications requiring accurate positioning and motion control. This stage enables movement along the X, Y, and Z axes, offering versatility and flexibility in various operations.

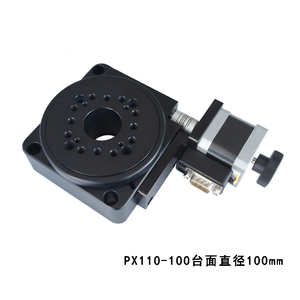

The 3 axis stage typically features high-precision motion control with resolution down to micrometer levels. It can support heavy loads while maintaining stability and accuracy. The stages are usually constructed from high-quality materials like aluminum or stainless steel to ensure durability and reliability. Additionally, some models come equipped with stepper motors or servo motors for enhanced control and performance.

The 3 axis motorized stage integrates motorized actuators into the stage design, allowing automated and programmable movements. This feature enables precise positioning and repeatability, crucial for tasks requiring consistent motion control. The motorized stage offers smooth and efficient operation, making it ideal for applications demanding high throughput and accuracy.

The 3 axis linear stage finds extensive use in various industries, including semiconductor manufacturing, biotechnology, optics, and electronics. It is employed in processes such as microscopy, imaging, laser processing, and inspection systems where precise positioning is essential. The linear stage plays a vital role in enhancing productivity and quality in automated production environments.

The Thorlabs 3 axis stage is renowned for its exceptional quality, reliability, and precision. Thorlabs, a leading manufacturer in the photonics industry, produces high-performance stages designed for demanding applications. These stages offer advanced features such as integrated encoders, high-resolution positioning, and compatibility with industry-standard software, making them a preferred choice for researchers and engineers.

When selecting a 3 axis translation stage for your specific application, consider factors such as load capacity, travel range, resolution, speed, and compatibility with existing systems. Evaluate the technical specifications of the stage to ensure it meets your requirements for accuracy and performance. Consulting with suppliers or manufacturers can help you make an informed decision based on your application needs.

To maintain optimal performance of your 3 axis stage, regular upkeep is essential. Keep the stage clean from debris or contaminants that may affect its operation. Check for any signs of wear or damage, such as worn-out components or loose connections, and address them promptly. Lubricate moving parts as recommended by the manufacturer to prevent friction and ensure smooth operation.

In conclusion, the 3 axis stage is a versatile and indispensable tool in various industries requiring precise motion control and positioning. Whether you choose a motorized, linear, or translation stage, selecting a high-quality and suitable stage is paramount for achieving accurate and efficient operations. Understanding the technical specifications, design features, and maintenance requirements of the stage is crucial for maximizing its performance and longevity in your applications.