Inner Side 90 Degree Connecting Corner Profile Aluminium T-slot Accessory Aluminium Profile Connector

High Quality Aluminum Casement And Sliding Window Profiles With Powder Coating Surface Treatment For Sale

Aluminum siding corners are integral components in various construction and design applications. These versatile elements serve as functional and aesthetic enhancers in projects ranging from commercial buildings to home renovations. Aluminum, known for its durability and lightweight nature, is the material of choice for these profiles.

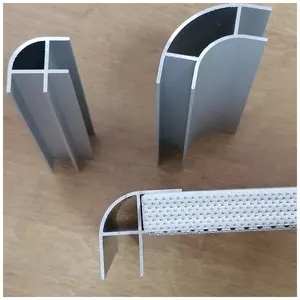

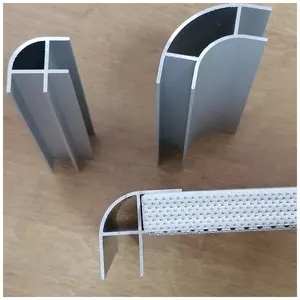

There is a diverse array of shapes available to meet the needs of different projects. L-angled profiles are commonly used for their structural integrity and ease of installation. Square and solid round tubes offer a blend of strength and sleek design, suitable for modern aesthetics. For more complex structures, T-shaped bars and hollow tubes provide versatility. Finishing touches are provided by J caps, Z clips, and dividers, which ensure a clean and polished look.

Aluminum siding corners are not limited to their namesake application. They extend their utility to office furniture, enhancing durability and contributing to sleek design. In lighting fixtures, they are prized for their heat resistance and ease of molding into complex shapes. The automotive industry utilizes these profiles for lightweight and corrosion-resistant components. Furthermore, their application in plumbing showcases their adaptability and resistance to environmental factors.

The majority of aluminum siding corners are crafted from 6000 series aluminum alloys, offering a balance between strength and workability. The temper of these alloys typically ranges from T3 to T8, indicating the level of hardness and strength. Surface treatments such as powder coating and PVDF coating are applied to enhance durability and aesthetic appeal. Anodizing and electrophoresis provide additional color options and improve corrosion resistance, while polishing achieves a reflective finish. For a natural look, a wood grain finish can mimic the texture of real wood, ideal for decorative purposes.

Customization is a key aspect of aluminum siding corners, allowing them to meet specific project requirements. Thickness can be adjusted, with a typical range from 0.2mm to 20mm. As for aesthetics, a spectrum of colors is available, from classic whites and silvers to vibrant blues and yellows. This flexibility ensures that the final product aligns with the design vision of any project.

Selecting the appropriate aluminum siding corners requires consideration of the application, desired features, and specific design requirements. With a vast selection of shapes, treatments, and colors, finding the right match for your project is simplified. Browse a comprehensive collection to identify the profiles that align with your construction or design needs.