Exploring the Versatility of Casting Rubber Molds

Casting rubber molds are pivotal in various manufacturing processes, offering the flexibility to create intricate designs and replicate details with precision. These molds are essential for producing a wide range of items, from intricate rubber mold jewelry casting to larger architectural features. The adaptability of rubber casting materials, including silicone rubber moulds and latex options, allows for their application across industries, catering to both functional and aesthetic requirements.

Types and Applications of Rubber Molds

The diversity of rubber molds, such as rubber moulds for plaster of paris and silicone rubber resin molds, is vast. These molds are not limited to small items but also extend to larger designs, including decorative elements like bolection molds. The application of rubber mould casting spans various sectors, including construction, art, and consumer goods, demonstrating the material's versatility in creating both functional and decorative objects.

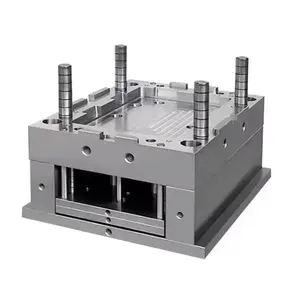

Features and Material Selection

When selecting a mold, the choice of material is crucial. Options range from iron to advanced bbdino super elastic silicone, each offering unique features. Silicone rubber, known for its heat resistance and non-stick properties, is ideal for complex geometries. In contrast, latex molds, such as latex moulds for plaster of paris, offer excellent elasticity, making them suitable for detailed casts. The decision on the material impacts the mold's durability, finish, and the level of detail it can capture.

Advantages of Standardizing Molds

Optimizing production efficiency is possible by standardizing certain elements of casting rubber molds. Implementing uniform lift bars, connection sizes, and clamp slots can significantly reduce setup times and streamline the manufacturing process. This approach not only enhances compatibility across various products but also aids in maintaining consistency in output quality.

Customization and Precision

Customization plays a key role in the creation of rubber molds for casting. Suppliers on Alibaba.com collaborate with clients to refine their molds, conducting multiple tests to ensure precision. This iterative process ensures that the final rubber casting material meets the specific requirements of the product, whether it's for rubber moulds for resin or pouring silicone rubber for intricate designs.

Choosing the Right Rubber Mold for Your Needs

Alibaba.com connects buyers with a plethora of suppliers, each offering a range of casting rubber molds to suit various applications. Whether you're in need of castable silicone rubber for detailed art pieces or robust molds for industrial components, the platform facilitates the discovery of the right resources to meet your project's demands. With a focus on precision and customization, suppliers ensure that the molds align with your production goals and design specifications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4