Understanding Cnc Atc Spindles

The term CNC ATC Spindle denotes an Automatic Tool Changer (ATC) element commonly present in Computer Numerical Control (CNC) machines. This component is vital for a variety of businesses spanning manufacturing facilities, machinery repair workshops, and suppliers of construction materials, particularly where precise and efficient cutting, milling, or shaping operations are essential.

The primary role of the CNC ATC Spindle is to secure and switch tools throughout the manufacturing process. This is accomplished through a sophisticated mechanism enabling the machine's controller to transmit a signal to the ATC. Subsequently, the ATC moves to the specified tool position, secures the tool, and initiates the machining process. Upon completing the task with a specific tool, the spindle releases the tool, moves to the next tool position, and repeats the cycle.

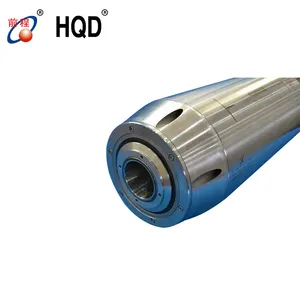

CNC ATC Spindles are crafted for enterprises necessitating high-speed and high-precision machining. These spindles feature robust motors and multiple bearings to ensure stability and longevity during swift tool changes. The technology underpinning these spindles is advanced, emphasizing minimal runout and offering adequate clamping force to securely hold tools in place during demanding operations.

Varieties of CNC ATC Spindles

CNC ATC spindles are available in diverse types tailored to different machinery needs and operational settings:

-

Belt-Driven ATC Spindle: These spindles utilize a system of pulleys and belts for power transmission from the motor to the spindle, commonly used in applications where precise accuracy is not a critical factor.

-

Direct-Drive ATC Spindle: This type directly links the spindle to the motor, eliminating the necessity for belts. Such design offers quicker responses to tool changes and can be advantageous in high-speed machining scenarios.

-

Hydraulic ATC Spindle: Although less common, these spindles are suitable for heavy-duty applications requiring high torque and power. The hydraulic system enables rapid tool changes and can accommodate large tools.

-

Electric ATC Spindle: An electric ATC spindle employs a servo motor for tool changes, blending speed and precision, often proving more energy-efficient compared to hydraulic systems.

Each type serves a specific purpose in various industries based on the distinct demands of the supported manufacturing tasks.

Selection Criteria for Cnc Atc Spindles

When choosing a CNC ATC spindle for business needs on Alibaba.com, it is crucial to consider various factors closely associated with the intended application.

Firstly, evaluate the compatibility with your existing machinery or production line requirements. The selected spindle should align with the specifications of your CNC router or machining center concerning mounting, power needs, and operational criteria.

Secondly, contemplate the materials you will predominantly work with. Materials such as aluminum or brass demand high-speed spindles with distinct characteristics compared to denser materials like hardwood or certain metals.

Furthermore, assess the complexity and quantity of workpieces. For extensive production runs or intricate designs, an ATC spindle could offer substantial time savings and diminish labor costs compared to manual tool changes.

Lastly, consider any post-sale service needs like maintenance assistance or spare parts availability. Opting for a supplier offering comprehensive technical support can ensure uninterrupted equipment operation.

Exploring Cnc Atc Spindles on Alibaba.com

Alibaba.com serves as a global marketplace connecting enterprises with a wide array of CNC ATC spindles suitable for diverse applications across various industries. With over two decades of experience in facilitating B2B transactions, Alibaba.com has become a crucial resource for companies aiming to enhance their manufacturing processes with efficient solutions. The platform's extensive supplier network guarantees businesses can discover the ideal CNC ATC spindle tailored to their specific requirements, whether for woodworking, metalworking, or other precision applications.

The user-friendly interface of the site allows buyers to interact directly with suppliers, negotiate terms aligning with their business needs, and ensure receipt of products meeting their expectations. Additionally, Alibaba.com's Trade Assurance service provides an extra layer of security by safeguarding payments until buyers confirm satisfactory order delivery.

Opting for Alibaba.com as a wholesale source of CNC ATC spindles grants access to a global product selection catering to major industries while benefiting from features simplifying international trade. The platform's dedication to supporting small and medium-sized enterprises is evident through its comprehensive support services and specialized trade solutions.

FAQs on Cnc Atc Spindles

What is the industrial application of CNC ATC Spindles?

CNC ATC Spindles are utilized in industrial machinery to facilitate automated tool changes and operations, enhancing efficiency and flexibility in manufacturing processes. They are indispensable in sectors such as manufacturing plants, CNC machining, and milling where rapid tool changes are frequent.

How does a CNC ATC Spindle operate?

A CNC ATC Spindle operates by leveraging a computer program to oversee its functions. It adheres to the program's directives to move to designated positions and execute predetermined tasks like drilling, milling, or cutting to produce parts or components.

What are the primary components of a CNC ATC Spindle?

Key components include a spindle motor providing cutting or milling power, a spindle securing the cutting tool, and a tool changer enabling automatic tool changes. These components collaborate to enable high-precision and high-efficiency machining.

How should one select the appropriate CNC ATC Spindle for business needs?

The selection should be based on specific business requirements such as material types, precision and speed prerequisites, compatibility with existing machinery, and the level of post-sale support needed.

From what materials are CNC ATC Spindles commonly manufactured?

CNC ATC Spindles are often made from robust materials like steel, aluminum, and stainless steel to ensure durability and performance under repetitive utilization. The choice of materials may vary based on the spindle's intended application and required precision levels.

Can CNC ATC Spindles be applied to any material?

While versatile, CNC ATC Spindles are designed for specific materials requiring precision processing. It is crucial to select a spindle compatible with the materials you frequently work with.

What factors should be considered when determining the size of a CNC ATC Spindle?

Consider the size of the material to be worked on and the components or parts to be machined. The spindle must be large enough to accommodate the workpiece while fitting within the machine's workspace comfortably.

Are there different types of CNC ATC Spindles available?

Indeed, various types of CNC ATC Spindles exist, including belt drive, direct drive, and pneumatic spindles. Each type offers distinct advantages in terms of speed, precision, and maintenance requirements.

How can one ensure the compatibility of a CNC ATC Spindle with machinery?

Refer to the manufacturer's specifications of the CNC ATC Spindle and compare them with those of the machinery or seek advice from a professional technician. Ensuring the spindle is designed to fit your equipment is crucial before making a purchase.

Which control systems are commonly paired with CNC ATC Spindles?

Common control systems used with CNC ATC Spindles encompass Syntec, Mach3, Richauto, and Siemens. These systems enable precise control over spindle operations, crucial for achieving required performance and efficiency in automated machining processes.

Can existing tools be used with a CNC ATC Spindle?

Compatibility with existing tools depends on the type of tool holder and the spindle's size and design. Ensuring the tool holder aligns with the spindle is essential to prevent damage.

How frequently should maintenance be performed on a CNC ATC Spindle?

Regular maintenance is essential to sustain optimal operation of a CNC ATC Spindle. This typically includes cleaning, lubrication, and inspection for signs of wear or damage. Refer to the manufacturer's guidelines for specific maintenance recommendations.

Is it feasible to upgrade existing machinery to incorporate a CNC ATC Spindle?

Some machines may be upgradeable for a CNC ATC Spindle, contingent on their design and compatibility with features like computers and installation space. Consulting a professional technician before any upgrades is advisable.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4