Understanding CNC Tables

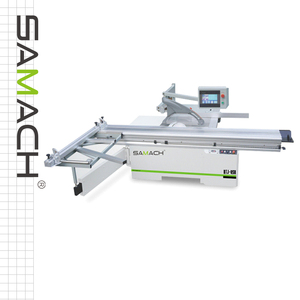

CNC tables are integral components of modern manufacturing and woodworking industries. These platforms are designed to accommodate various CNC (Computer Numerical Control) machines, including wood routers, plasma cutters, and saw machines. The versatility of CNC tables allows for their application in diverse settings, from manufacturing plants to machinery repair shops and even building material shops.

Types and Applications

The range of CNC tables includes models compatible with different control systems such as DSP (Digital Signal Processor), NC Studio, and RichAuto. Depending on the specific needs of a task, users can select from a CNC router table, an ATC (Automatic Tool Change) CNC router table, or a CNC engraving machine table. These tables are pivotal in precision cutting, engraving, and shaping of materials in various industries.

Features and Materials

A CNC router table is often characterized by its robust construction and precision engineering. Materials used in the construction of these tables are selected for durability and stability, ensuring minimal vibration during operation. Features may include compatibility with various control systems like Mach3 or Syntec, enhancing the machine's adaptability to different production environments.

Advantages of CNC Tables

The advantages of utilizing a CNC plasma table or router table are manifold. They offer enhanced precision in cutting and shaping materials, which is crucial for high-quality manufacturing. The automation of CNC tables also increases efficiency, reducing the time and labor typically required for complex tasks. Furthermore, the adaptability of these tables to various control systems and their suitability for a range of materials make them a valuable asset in any production setting.

Choosing the Right CNC Table

Selecting the appropriate CNC machine table involves considering the specific requirements of the task at hand. Factors such as the size of the table, the type of control system it supports, and the intended application are crucial. Whether for intricate woodworking projects or heavy-duty metal cutting, there is a CNC table designed to meet the challenge.

Conclusion

In conclusion, a CNC cutting table is more than just a surface for mounting machinery; it is a sophisticated tool that enhances the capabilities of CNC machines. By providing stability, precision, and versatility, these tables play a critical role in the efficiency and quality of modern manufacturing processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4