A filament extruder is used in the 3D printing process to produce filament, the material used to create 3D printed objects. It is designed to melt and shape plastic pellets or granules into a continuous filament strand. They are commonly used by individuals or small businesses to produce custom filaments.

Types of Filament Extruders

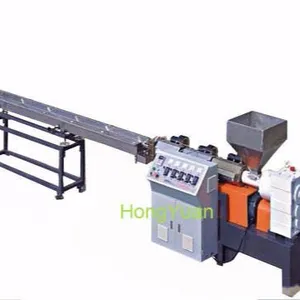

There are three main types of 3d filament makers: desktop filament extruders, industrial filament extruders, and dual filament printers. Desktop filament extruders are compact and affordable for small-scale production or personal use. They are usually manually operated. Industrial filament extruders are larger and more powerful, capable of handling higher volumes of plastic material. They often offer more advanced features like automated controls and precise temperature regulation. A dual filament 3d printer has two nozzles, simultaneously extruding two different filaments. This saves time and eliminates the need for post-processing steps. A dual extruder is commonly used in multi-color or multi-material 3D printing applications, where the extruder can switch between filaments during the printing process. For example, it allows for functional prints with rigid and flexible parts in the same object. The two filament 3d printer can also create 3D prints with intricate color patterns, gradients, or even full-color designs.

Components of a Filament Extruder

The filament maker consists of several components, including a hopper, a heating system, and a nozzle. A hopper is a container that holds the plastic pellets or granules, the raw material for filament production. The hopper feeds the plastic material into the extruder. The heating system consists of heating elements or a heating barrel that heats the plastic material to its melting point. This can be achieved through electric heaters or hot air. The nozzle is the opening through which the molten plastic is extruded to form the filament. It determines the diameter and shape of the filament.

Operating Requirements of A Filament Extruder

A 3d printer filament maker typically requires a stable and reliable power supply. Filament extruders operate at high temperatures and involve molten plastic, which can be hazardous if improperly handled. It is crucial to follow safety guidelines, including wearing appropriate protective gear such as gloves and safety glasses. Another important consideration is that the operator should ensure the filament extruder is properly calibrated and adjusted. This involves regularly checking and fine-tuning the temperature settings, feed rate, and nozzle diameter to ensure consistent and accurate filament production. Improper calibration can result in filament with inconsistent diameter or poor quality, leading to issues during 3D printing. Additionally, the extruder is supposed to be placed on a stable surface and away from flammable materials. Regular maintenance and cleaning are necessary to keep the filament extruder in optimal condition. This may involve removing plastic residue or debris from the extruder's components, checking for wear and tear, and lubricating moving parts as needed.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4