In the art of chocolate creation, the selection of a mold is as pivotal as the caliber of the chocolate used. Polycarbonate chocolate molds are the pinnacle of choice for chocolatiers seeking to craft confections with a professional sheen and elaborate designs. These molds are lauded for their unparalleled ability to impart a lustrous finish, sharp contours, and consistent forms, securing their place as a fundamental tool in the industry.

Types of Polycarbonate Chocolate Molds

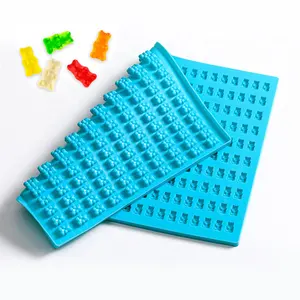

Variety abounds within the realm of polycarbonate chocolate molds, accommodating an extensive range of styles and functions. Beyond traditional bars and bonbons, there are polycarbonate candy molds for assorted sweets, custom polycarbonate chocolate molds for bespoke creations, and specialized versions like polycarbonate easter egg moulds for festive confections. Each design is meticulously crafted to fulfill distinct requirements, be it for large-scale production or artisanal chocolate making. For example, chocolate world polycarbonate molds are celebrated for their complex geometric impressions, while magnetic polycarbonate chocolate molds provide the precision needed for aligning transfer sheets or inserts in filled chocolates.

Structure of Polycarbonate Molds

The architecture of polycarbonate molds reflects the sophisticated engineering that underpins these indispensable instruments. Comprising a sturdy plastic framework with cavities polished to perfection, these molds guarantee chocolates emerge with a flawless surface. Features such as alignment pins or magnets aid in securing mold halves for filled chocolates or intricate figures. The clear nature of polycarbonate permits chocolatiers to oversee the setting process, ensuring each cavity is filled adequately and the chocolate's crystallization is on course.

Materials and Properties

The deliberate choice of polycarbonate for these molds stems from its superior thermal conductivity, which promotes uniform heat distribution vital for chocolate tempering. Polycarbonate's chemical resistance means it remains unaffected by flavorings or colored cocoa butter. Its structural integrity ensures consistent outcomes over time, striking a balance between practicality and longevity, and offering chocolatiers a dependable implement for their craft.

Business Usages and Applications

Polycarbonate chocolate molds are essential across various commercial contexts. In the realm of upscale confectionery, they are employed to produce artisanal chocolates for boutique sales, extravagant wedding favors, and tailored corporate presents. For larger enterprises, such as chocolate factories and gourmet food producers, these molds are instrumental in delivering uniform, premium products crucial for maintaining brand uniformity. Their robustness and user-friendliness are ideal for sustained, high-volume output, essential to fulfilling the demands of a commercial enterprise.

Functions of Chocolate Molds

The fundamental role of polycarbonate chocolate molds is to sculpt liquid chocolate into solid forms with a professional gloss. Designed for effortless chocolate release once set, these molds eliminate the need for bending or tapping that could mar the delicate treats. They also enable the crafting of hollow figures, like chocolate eggs or spheres, by coating the mold's interior with a thin chocolate layer. Such functional versatility empowers chocolatiers to diversify their offerings and appeal to a wider market.

Distinctive Features of Polycarbonate Molds

Notable attributes of polycarbonate chocolate molds include their high transparency, facilitating visual checks during filling and solidification, and their superior release qualities, ensuring chocolates emerge with a gleaming finish and crisp details. These molds are also designed to be stackable, conserving space and simplifying storage. The non-stick surface obviates the need for release agents, which could compromise the chocolate's flavor and texture.

Benefits of Using Polycarbonate Molds

Employing polycarbonate molds yields manifold advantages in chocolate production. They enhance efficiency on the production line, as their straightforward use and maintenance save time and labor. The uniformity they deliver aids in upholding a high standard of product quality, fostering consumer confidence and allegiance. For businesses, this equates to an improved brand reputation and the potential for increased sales. Moreover, the durability of polycarbonate molds renders them a cost-effective option over time, as they necessitate less frequent replacement compared to other mold types.

How to Use and Maintain Polycarbonate Molds

To maximize the efficacy of polycarbonate chocolate molds, chocolatiers must first temper the chocolate correctly, a process of controlled heating and cooling to stabilize it for candy-making. Molds should be filled attentively to prevent air pockets and then vibrated gently to ensure chocolate settles into every detail. Once set, the chocolate should detach from the mold with a simple twist or tap. Cleaning is a breeze; just wash with warm water and a soft cloth or brush to eliminate any remnants. Abstain from abrasive cleaners or tools that could scratch the surface. Proper drying and storage are crucial to avert water spots or bacterial accumulation.

How do I choose the right polycarbonate chocolate mold for my business?

Selecting the appropriate mold for your enterprise involves assessing the desired product type, production volume, and requisite detail level. For high-volume, standard confections, basic bar or button molds may suffice. For specialized or artisanal chocolates, molds with complex designs or capabilities for filled chocolates might be preferable. Custom molds can also be crafted to mirror your brand or to create distinctive shapes that distinguish your products in the marketplace.

What are the advantages of using polycarbonate molds over silicone or metal?

Polycarbonate molds boast several benefits over their silicone or metal counterparts. They offer greater durability and yield a finer gloss and finish on chocolates. Unlike silicone, polycarbonate remains rigid, ensuring chocolates have a consistent thickness and form. Metal molds are susceptible to rust and often necessitate a release agent for chocolate removal, which is not the case with polycarbonate molds.

How can I ensure the longevity of my polycarbonate chocolate molds?

To prolong the life of your polycarbonate chocolate molds, proper care, cleansing, and storage are key. Post-use, they should be washed with warm water and a gentle detergent, then thoroughly dried before being put away. Keeping the molds in a cool, dry location out of direct sunlight will prevent distortion and extend their usability. Additionally, eschewing sharp implements or harsh cleaning agents will preserve the molds' smooth surfaces.

Explore an extensive assortment of polycarbonate chocolate molds near me on Alibaba.com, where a plethora of mold options awaits to elevate your chocolate-making endeavors. Whether in search of seasonal motifs, classic bar configurations, or entirely unique custom designs, Alibaba.com connects you with a wide network of manufacturers and suppliers to fulfill every confectionery requirement.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4