A powder-coating gun is an industrial tool used to apply powder coating to a substrate, primarily metals. In comparison to traditional painting techniques, powder coating offers a more durable finish. It is typically longer-lasting, with most powder coatings maintaining their integrity for approximately 15-20 years before showing signs of weathering.

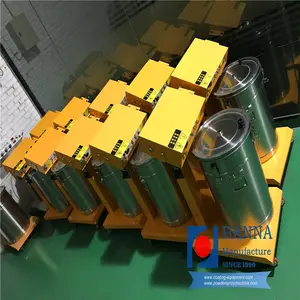

Various types of powder-coating guns

Tribo guns: Tribo guns operate based on the principle of triboelectric charging, in which the powder acquires a positive charge by creating friction against the inner wall of the gun. The statically charged powder particles adhere firmly to the substrate, resulting in a robust bond. This powerful adherence results from a process known as electrostatic attraction. Since opposites attract, the positively charged powder tightly binds to the negatively charged or grounded substrate.

Electrostatic spray guns: Contrary to the Tribo gun, an electrostatic spray gun gives a negative charge to the powder particles. This process creates a consistent and evenly spread coating, making it suitable for complex structures and shapes. The charging method involves a high-voltage application to the tip of a spray gun's electrode. As the powder moves through the coating gun, it flies by the charged electrode, which ionizes the nearby air, subsequently imparting a negative charge to the powder particles. The negatively charged particles are then attracted to the grounded or positively charged substrate, forming a tight electrostatic bond.

Hot flocking guns: A hot flocking gun offers distinct advantages. The substrate coated is pre-heated, and the adhesive is applied before the powder spraying process. The heat facilitates the immediate bonding of powder particles, resulting in a thick coating ideal for corrosion protection. The more substantial coating achieved through this method provides a significant barrier, impeding corrosive substance penetration and rust propagation on the substrate.

Key features of powder coating guns

Ease of use: Powder-coating guns incorporate simplicity in design. Most models feature a one-button operation, adjustable powder flow, and voltage control. For example, adjusting the powder flow in an electrostatic spray gun can assist in achieving a more evenly spread coating.

Efficient powder usage: Powder coating guns are renowned for their efficiency in powder use. For instance, an electrostatic spray gun facilitates more extensive coverage per pound of powder than traditional painting methods.

Portability and lightweight: Most powder-coating guns are lightweight and portable. A user can conveniently maneuver a tribo gun or flocking gun around intricate parts, improving the quality of the coating process. Visit Alibaba.com to explore more designs and options of power coating guns!

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4