Introduction to Shredder Blades

Shredder blades are essential components in various shredding systems used to process materials into smaller sizes. These blades are engineered to fit a range of equipment, from paper shredder blade assemblies to wood shredder blades for heavy-duty lumber processing. The design and manufacturing of these blades ensure they meet the demands of different shredding tasks.

Types and Applications of Shredder Blades

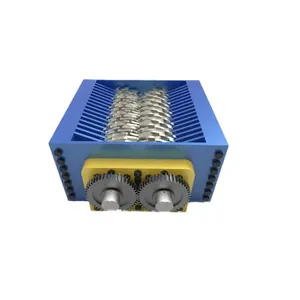

The versatility of shredder blades is evident in their applications. Plastic shredder blades are crafted to tackle different plastic types, while blades for chipper machines are robust, designed for chipping wood into finer pieces. Double shaft shredder blades are used in more complex machinery, providing efficient shredding for a variety of materials. The diversity in blade types caters to specific industry needs, from recycling to manufacturing.

Features and Materials

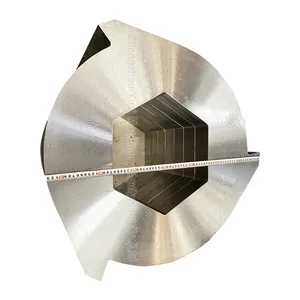

Shredder machine blades are predominantly made from hardened steel, chosen for its durability and resistance to wear. The treatment of these blades includes a heat process that enhances their longevity and maintains their sharpness over time. The construction of metal shredder blades ensures a finished surface that minimizes the risk of corrosion and rust, which is crucial for maintaining performance in harsh environments.

Advantages of Upgraded Shredder Blades

Upgrading to new shredder blades can significantly improve the efficiency of machinery. These blades are designed for easy installation, allowing for quick replacement and minimal downtime. The improved design of plastic crusher machine blades and chipper replacement blades ensures compatibility with a wide range of machines, enhancing the performance of existing systems. The specialized treatment of these blades also contributes to a more consistent output, ensuring materials are shredded to the desired size.

Customization and Compatibility

Customization is a key aspect when selecting the right blade for shredder machinery. The ability to customize the size and shape of crusher blade components allows for a perfect fit with existing equipment, ensuring optimal performance. This flexibility is crucial for businesses looking to maintain or enhance their operational capabilities without the need for complete equipment overhauls.

Conclusion

In conclusion, shredder blades are a critical investment for businesses that require material size reduction. Whether it's for a garden shredder or an industrial recycling plant, the right types of shredder blades can make a significant difference in the efficiency and effectiveness of the shredding process. With a focus on durability, ease of installation, and customization, these blades are designed to meet the rigorous demands of various shredding applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4