Types of electric cone yarn winder

An electric cone yarn winder is a knitting aid that helps change the structure of yarn from hanks or skeins into cones. Winders can be used for all types of yarn, but it is essential to check the machine's compatibility with certain yarns before use. Electric yarn winders are usually big, heavy-duty machines built for industrial or commercial use. They often come with advanced features like multiple-speed settings, automatic yarn center finding, and programmed yarn winding patterns.

Because they are plugged in or run with a battery, electric yarn winders are more convenient than manual or hand crank winders. All the user has to do is to press the button for the yarn to be wound and organized into a cone. The variety of functions makes it possible to create a jumbled cone of yarn with any type of yarn on the market with just a press of a button or flick of a switch. Electric yarn winders are faster than their hand-cranked counterparts and can usually wind upwards of 4 to 5 ounces per minute.

One major drawback of electric yarn winders is their high price point compared to manual winders. Additionally, they are not portable like hand crank yarn winders, which are the size of a small box and can be taken anywhere.

Like all yarn winders, electric cone winding machines come in different models. Buyers can look at the product specifications listed to get details on the dimensions and weights of each model.

Sample models include:

- Elan Electric Yarn Winder: The Elan Electric Yarn Winder is a great example of an electric yarn winder that winds yarns into yarn cakes - a popular format in the knitting world! This yarn winder is quite easy to use. All a person has to do is plug it in, select the winding speed, and press the "Start" button. The Elan Electric Yarn Winder has a programmable yarn winding pattern and can wind at various speeds.

- Himec Electric Cone Yarn Winder: The Himec winder comes with features such as automatic yarn feeding, stopping, and cutting, which are all important for a smooth winding process. It also has yarn tension control, which ensures that the yarn is wound at even tension throughout the cone. Other features to be on the lookout for when buying an electric yarn winder are anti-clockwise and anti-clockwise winding, remote control, sensor feeding, and automatic yarn cutting and feeding. The Himec winder is usually made out of metal, plastic, and electrical parts, which make it a long-lasting investment.

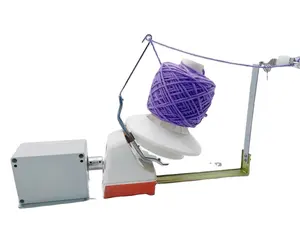

- Wool Winder with Creel: A proper wool winder is an essential tool for knitters and crocheters who want to store their yarn in an organized and user-friendly way. The creel holds the yarn in its original form and allows the yarn to easily feed into the winder without tangling or twisting. This is especially helpful for yarns that tend to kink up or become difficult to manage. Another great feature about electric wool winders is their clamping mechanism. Electric wool winders usually come with clamping mechanisms that make it easy and safe to clamp onto work surfaces. The clamping mechanism can be adjusted and fixed onto tables or boards of all sizes from 0 to 4".

Specifications and maintenance of the electric cone yarn winder

Specifications

Some crucial specifications of the yarn winder are as follow:

- Capacity: The amount of yarn that can be wound into a cone or ball at one time is measured in weight or length, such as 500 g/800 m.

- Speed: The winding speed denotes how quickly the yarn is wound onto the cone or spool. It is typically measured in meters per minute or feet per minute. This winding speed may impact productivity and efficiency.

- Power: The power rating of an electric cone yarn winder indicates its power consumption and is typically expressed in watts or kilowatts.

- Size and Weight: The physical dimensions and weight of a cone yarn winder are important to its space requirement and portability.

- Materials: The construction materials of the yarn winder include plastics, metals, and alloys, which influence the durability and stability of the device.

- Design: The design of a yarn winder machine affects how easy it is to use and the amount of maintenance it requires.

- Function: The functions of an electric yarn winder, such as automatic winding, multi-thread simultaneous winding, and reverse winding, affect its application range and convenience.

Maintenance

Regular maintenance of a yarn winder machine is crucial to its durability and efficiency. Here are some maintenance methods for your reference:

- Cleaning: Regularly clean the surface and internal parts of the yarn winder to remove dust and yarn residues. Clean the yarn winder with a soft brush or cloth and a small amount of detergent. Avoid using excessive water or cleaning agents to prevent damage to the machine.

- Lubrication: Lubricate the moving parts of the yarn winder regularly to ensure smooth operation. Apply an appropriately selected lubricant to the designated locations, such as bearings and gears. Additionally, regularly wipe and clean the lubricant on the machine to prevent dirt buildup.

- Inspection: Regularly check various parts of the yarn winder for signs of damage, such as loose, worn, or damaged, and timely repair or replacement as needed to ensure its proper operation.

- Adjust: Periodically adjust the functions and parameters of the yarn winder to ensure that it is appropriately adapted to the winding requirements. For example, adjusting the winding speed, tension, etc. Also, check whether the functions of the machine are working properly.

- Prevent moisture and dust: Keep the working environment of the yarn winder dry and clean. Avoid placing it in a damp and dusty place to prevent damage to the machine.

Applications of electric cone yarn winders

The following sectors can make good use of electric cone yarn winders:

- Textile industry: Fabrics, carpets, curtains, apparels, seat covers, bags, turf, gegrids, gaskets, and other products require winding of yarns. Different kinds of yarns like cotton, silk, wool, nylon, polyester, and blended yarns can be used. Large winding machines with 36 or more spindles are suitable for usage in this industry.

- Knitting factories: These are perfect places to use yarn winders when work needs to be done quickly and efficiently. Sophisticated yarn winders can fulfill the knitting machines' feeding requirements.

- Spinning mills: Frequent changes in bobbin weight and size are requirements in this sector. Speed, capacity, and automation features are significant. Spinning mills will need Electric yarn winder machines that have a lot to offer in these aspects.

- Tailoring businesses: Electric yarn winding machines help by making the job easier and faster. These machines can be preset to measure the length of yarn needed for different types of clothes. Electric winders for tailoring are available in portable and bench-top designs so tailors can use them conveniently.

- Embroidery and sewing companies: Use of these machines will save time, effort, and materials when straight, blind, satin, overlock, and other sorts of seams are to be embroidered or sewn. The electronic cone yarn winder can be used to pre-wind the yarns used for embroidering and sewing.

- Hobby businesses: Small businesses that work like a home economy will find compact and small machines useful. It is also perfect for use when space is limited.

How to Choose Electric Cone Yarn Winders

When selecting an electric yarn winder for sale, buyers should consider its winding speed. High winding speed is an important feature for knitting and weaving industries because it directly affects the production efficiency of the industry. Efficient cone-winders can help to increase yarn-repairing speed, result in less downtime, and improve overall productivity.

Additionally, buyers should take the compatibility with different yarn types into consideration. Versatile yarn-winders that can handle various yarn types and weights are useful for businesses that work with multiple yarn specifications. Such ease of use can also facilitate the smoothest transitions among different projects and reduce the need for additional equipment.

Also, the durability and build quality of the yarn winders are essential for most businesses' operations. Frequent use of the machines can wear them down quickly, leading to damaging downtime. Durable yarn winders can withstand regular use and come with low-maintenance requirements, reducing operational costs in the long run.

Electric cone yarn winders with intuitive controls and setup are easy to use and excellent for training new employees. Their user-friendly designs help to reduce staff training costs and ensure a smooth transition among employees. Furthermore, buyers should select yarn winders with excellent yarn tension control. Proper yarn tension prevents yarn tangling and ensures smooth feeding during knitting and weaving processes.

Finally, buyers should look for winders with excellent after-sales support services. Reliable after-sales support can provide businesses with peace of mind and ensure prompt assistance in case of any issues or repairs required with the equipment.

Q&A

Q: Which motor is used in a yarn-winding machine?

A: Generally, the AC gear motor is used in an electric cone yarn winder machine, but that may change depending on the design.

Q: How many types of yarn winding machines are there?

A: There are quite a number of yarn winding machines. The key types include automatic yarn winding machines, cone rewinding yarn machines, cheese or pirn winding machines, shuttle-less winding machines, and others.

Q: What is the relationship between the yarn winding machine and weaving?

A: The yarn winding machine prepares the yarns for weaving. It winds the threads into convenient shapes such as cones or bobbins for easy management during the weaving process. Weaving is the next major step in the textile production process after yarn winding.

Q: Can a yarn winding machine be used for other types of threads?

A: No, generally, yarn winding machines are designed with features to handle the complexity of winding yarn. However, some may be able to wind other threads upon customization.