(1591 products available)

As people's lives are getting busier and busier, many people are looking for a way to make fresh pasta fast and efficiently. The electric pasta roller machine is a great solution. It is a modern machine that can make pasta by pressing and rolling the dough. The electric pasta machine has three main types. The first type is the electric extruder pasta machine. It works by forcing the dough through a die to create various pasta shapes. This type is ideal for making large quantities of pasta quickly. It is also suitable for commercial settings.

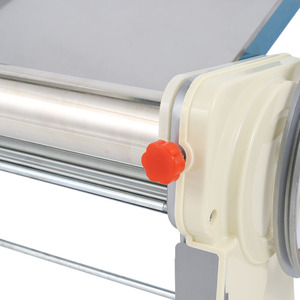

The second type is the electric dough sheeter. It features two to three rollers that roll the dough into thin sheets. This type of machine is used with a cutting attachment to cut the pasta into different shapes. The electric dough sheeter is easy to use and can produce a large amount of pasta. The third type is the combination pasta machine. This machine has an electric motor that can roll the dough into thin sheets and then cut it into various shapes. The combination pasta machine offers versatility and convenience. It is suitable for those who like to make different kinds of pasta.

Some electric pasta machines also come with additional features, such as an automatic pasta cutter and multiple speed settings. These features make the machine more convenient and efficient. No matter what type it is, the electric pasta machine is designed to save time and labor. It is suitable for both home and commercial use.

The specifications of an electric pasta machine may vary depending on the model and brand, but certain key features are common to all of them.

Motor power: The motor power of an electric pasta machine is a critical specification because it determines the machine's capacity to knead and roll out the pasta dough. Motor power is usually expressed in watts or horsepower (HP). Higher motor power means faster processing and handling of the dough.

Pasta shape and thickness settings: Electric pasta machine usually have different shapes and thickness settings to produce various types of pasta, such as spaghetti, fettuccine, and lasagna. The number of shaping and thickness settings may vary depending on the model of the machine.

Production capacity: This is the amount of pasta the machine can produce in a given period. It is usually measured in kilograms or pounds per hour. The production capacity of an electric pasta machine can vary depending on the type and model. For example, commercial-grade machines have a higher production capacity than household machines.

Safety features: Electric pasta machines are equipped with various safety features to prevent accidents and ensure safe operation. Some of the safety features include overload protection, emergency stop buttons, and safety guards.

Apart from the above specifications, the electric pasta machine must be properly maintained to function optimally and guarantee longevity. Regular cleaning and maintenance are essential to ensure food safety and hygiene. The machine should be cleaned after use to remove any dough residue. Also, the parts that can be disassembled should be cleaned separately. This includes the dough rollers, cutting plates, and the cutting blades.

Another maintenance tip is to lubricate moving parts using food-grade lubricants. For example, the bearings and rollers should be lubricated to minimize friction and extend the life of the electric pasta machine. In addition, the machine should be stored in a dry and clean place when not in use to prevent rust and corrosion. It is also good to cover the machine with a dust cover or cloth for extra protection. Most importantly, one should refer to the manufacturer's instructions for specific maintenance requirements for a particular model of the electric pasta machine.

An electric pasta roller machine is not only a crucial kitchen equipment but also used in various scenarios.

Restaurants, catering companies, and food trucks can use electric pasta makers to make fresh pasta. These businesses can use the machine to make different types of pasta dishes. This can help them offer unique dishes to their customers and set themselves apart from their competitors.

Some homeowners use electric pasta makers to make fresh pasta at home. They can use the machine to make fresh pasta for their family and guests. This can help them create memorable dining experiences. Moreover, such an electric pasta machine can be used to set up small-scale pasta-making businesses at home.

Some hotels use electric pasta machines to make fresh pasta for their guests. Providing guests with freshly made pasta can help enhance their dining experience and improve customer satisfaction.

Fast-food restaurants and takeaway joints can use electric pasta makers to make different types of pasta quickly. These businesses can use the machine to make fresh pasta dishes to meet customer demand. Using electric pasta machines can help enhance customer experience.

Large-scale food processing companies can use electric pasta machines to produce pasta on a mass scale. An electric pasta maker can help increase production efficiency and meet high-volume demands. The machines can be used to make different types of pasta shapes and sizes. This can help these companies meet the needs of their customers and maintain competitiveness in the market.

When choosing the ideal electric pasta maker machine, it is crucial to consider the following factors:

It is important to consider the type of pasta that one wants to make when choosing a pasta maker machine. While some machines are designed to make different types of pasta, others are specifically made for a particular type of pasta. For instance, pasta extruders are best suited for making hollow pasta shapes like ziti and macaroni, while pasta rollers are perfect for making traditional pasta sheets. Buyers should also consider the pasta size options the machine offers. Some machines come with interchangeable dies and cutters, which allow them to make different pasta shapes and sizes.

Business owners should consider the production capacity of the machine they are interested in. They should choose a machine that can keep up with their demand. Larger restaurants and commercial kitchens that serve a lot of customers daily should go for heavy-duty machines with higher production capacities. On the other hand, smaller restaurants and food businesses with lower production demands can opt for tabletop machines.

Buyers should consider the power source and usage of the machine. They should opt for a machine that is compatible with their power source. If one has limited power outlets, they can opt for a machine that operates on a gas-powered generator or propane. In addition, buyers should choose a machine that is easy to operate and use.

It is important to choose a machine that is constructed with sturdy and durable materials. Such a machine can withstand the demands of a busy commercial kitchen. Additionally, the machine should be easy to clean, with most parts being removable and dishwasher safe.

Commercial business operators should consider their budget and choose a machine that meets their needs. They should choose a machine that offers good value for their money. Some expensive models may not be necessary for small food businesses with low production demands.

Q1: What are the benefits of using an electric pasta machine?

A1: Electric pasta machines offer many great benefits. They are faster and easier to use than manual machines. They also give a consistent thickness to the pasta dough. Another benefit is that most electric machines have a built-in cutter, so they can produce different shapes of pasta. Finally, the electric machines are usually more powerful than manual ones, so they can make a large amount of pasta in a short time.

Q2: What is the difference between a pasta extruder and roller machine?

A2: Roller machines make sheet pasta that is then cut into different shapes. Extruder machines push dough through a die to make pasta shapes. Roller machines are more common for home use, while extruder machines are used in commercial settings.

Q3: What is the best way to clean a pasta roller machine?

A3: The best way to clean a pasta roller machine is to follow the manufacturer's instructions. In general, the machine will need to be taken apart carefully. Some parts can be washed with dish soap and water, while others can only be wiped with a damp cloth. Some plastic parts can be put on the top shelf of the dishwasher. It is very important to dry the machine thoroughly before putting it back together.