What is Industrial High Shear Mixer

Industrial high shear mixers are specialized blending devices designed for the preparation of materials that are difficult to mix or disperse. These mixers are engineered to apply intense mechanical action, which is essential for achieving a thorough and uniform blend of various types of substances. They are commonly used in industries such as pharmaceuticals, chemicals, cosmetics, and food processing, where the quality of mixing is crucial for product effectiveness and consistency.

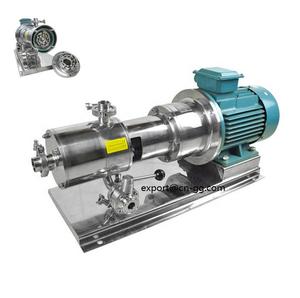

The principle of operation for an industrial high shear mixer involves the application of high mechanical energy to a mass of material, typically contained in a vessel. This energy is imparted by a rotor, often equipped with several blades, that rotates at high speeds. The mixing action can be further intensified by the addition of other elements such as a stator that acts to hold the mixture in place, creating shear forces that cut through the material and promote a homogeneous blend.

These mixers are designed for professionals who require a high standard of mixing, such as manufacturers, production plant operators, and research institutions. The efficiency and effectiveness of these mixers are grounded in their ability to generate high shear rates which ensure that the ingredients are mixed quickly and thoroughly. This is achieved through the careful design of the mixing elements and the power of the motor driving the rotation.

Types of Industrial High Shear Mixers

Industrial high shear mixers come in various designs and configurations to meet the diverse needs of different manufacturing processes. Here are some common types:

-

Batch High Shear Mixers: These are used for small-scale production runs. The mixing action is contained within a tank or vessel where ingredients are added and mixed. They are ideal for specialized applications such as pharmaceuticals or cosmetics.

-

In-Line High Shear Mixers: For larger volumes or continuous processing, in-line high shear mixers pass materials through a mixing chamber where they are subjected to intense shear forces. This type is often found in situations where space is at a premium or rapid mixing is required.

-

Laboratory High Shear Mixers: These are scaled-down versions used for research and development or small-scale production. They offer the same benefits as their larger counterparts but are tailored for smaller sample sizes.

-

Industrial High Shear Mixer for Powders: Specifically designed for solid-liquid or powder-powder mixing, these mixers are equipped with specialized impellers and can handle high viscosities. They're commonly used in industries such as construction materials or in the food industry for confectionery and bakery products.

How to choose Industrial High Shear Mixer

When selecting an industrial high shear mixer, it is crucial to consider the specific requirements of your business operations. Factors such as material viscosity, desired output volume, space availability, and required level of mixing intensity should all be taken into account.

For businesses in the food processing or pharmaceutical industries where product purity is paramount, opting for stainless steel 304 construction may be ideal due to its superior hygiene properties and resistance to corrosion. On the other hand, carbon steel units might be more suitable for heavy-duty applications in manufacturing plants that handle materials such as chemicals or explosives.

The core components of the mixer such as gears, motors, and bearings should also influence your decision since they affect both performance and maintenance requirements. It's advisable to choose units with well-designed after-sales support and maintenance services to ensure continuous operation without significant downtime.

Consider whether the mixer can be customized to accommodate specific industry needs while also ensuring compatibility with existing production lines in terms of volume and process flow.

About Industrial High Shear Mixer on Alibaba.com

Alibaba.com stands out as a global wholesale marketplace connecting businesses with a vast array of suppliers offering Industrial High Shear Mixers suited for any commercial need. No matter the scale of your operation or the specificity of your requirements, Alibaba.com simplifies the sourcing process by providing access to an extensive selection of machinery from suppliers around the world.

Businesses can confidently make purchases through Alibaba.com thanks to services like Trade Assurance that protect payments until delivery is confirmed. This commitment to secure transactions underscores Alibaba's mission to make international trade more accessible and reliable for small and medium-sized businesses.

Moreover, Alibaba.com supports customized solutions catering to unique industrial applications. Whether your business operates in food processing or chemical manufacturing, you can find suppliers offering tailored equipment that meets your operational demands. With user-generated content aiding in product selection and features that enable communication in local languages, Alibaba.com ensures that purchasing Industrial High Shear Mixers is not just about acquiring a product; it's about building a partnership with trusted suppliers who empower your business's growth and success in a competitive market.

Common FAQs for Industrial High Shear Mixer

What is the primary function of a high shear mixer?

A high shear mixer is designed to blend, disperse, and emulsify materials at a high velocity, producing a homogeneous mixture with a fine particle size distribution.

How does a high shear mixer work?

A high shear mixer operates on the principle of intense mixing and fluid shear, using a rotor-stator set inside a stator to create a high-velocity zone that subjects materials to both cutting and mixing action.

What are the key factors to consider when selecting a high shear mixer?

Important factors include the material the mixer will be used with, the required mixing intensity, the volume of the mixer, material construction for durability, and the ease of cleaning and maintenance.

Can high shear mixers be used for food processing applications?

Yes, high shear mixers are commonly used in food processing to prepare sauces, dressings, and other liquid products due to their ability to achieve a fine particle size and smooth texture.

Are there different rotor-stator materials available for high shear mixers?

High shear mixers come with rotors and stators made from various materials like stainless steel, titanium, or other metals depending on the application's requirements.

What is the advantage of having a variable speed control feature on a high shear mixer?

A variable speed control allows operators to adjust the mixing intensity, providing flexibility and precision for different materials and processes, enhancing the mixer's functionality.

How does the cooling system of a high shear mixer affect its operation?

The cooling system is crucial for managing the temperature during continuous operation, which prevents overheating and maintains the quality of the processed product.

What is the typical maintenance required for a high shear mixer?

Regular maintenance typically includes checking the rotor-stator set for wear and tear, ensuring the seals are tight, and cleaning the machine thoroughly after use to prevent clogging or contamination.

How do I determine the right size high shear mixer for my business needs?

Consider the volume of material you need to process, the space available in your facility, and the size of the machine. Analyze these factors to determine the appropriate model for your operations.

Can I get a customized high shear mixer tailored to my specific industry requirements?

Yes, many suppliers offer customized support including OEM and ODM services to tailor high shear mixers to specific industry requirements.

Are there safety features included in high shear mixers?

Modern high shear mixers often come equipped with safety features such as interlocking guards and emergency stop buttons to prevent accidents during operation.

What is the difference between a batch and continuous high shear mixer?

Batch high shear mixers operate in a batch mode where materials are processed in a discrete batch size, while continuous high shear mixers continuously process materials without stopping, ideal for high-volume operations.

How does the core material of a high shear mixer affect its performance?

The core material can influence durability and suitability for certain materials; for instance, stainless steel cores are robust and easy to clean, while composite materials may offer specific performance benefits like weight reduction or non-conductivity.

Is it possible to scale up a high shear mixer for increased production?

Yes, it is possible to scale up to larger capacity high shear mixers or integrate them into automated production lines to meet increased demands without compromising on performance.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4