(3646 products available)

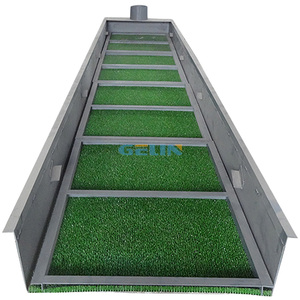

A mining sluice box is a channel or a trench in the ground used for the commercial purpose of gold extraction. Various types of mining sluice boxes are available for mining industries.

Riverbed Sluices:

Rugged river sluice boxes are designed for in-stream or riverbed gold recovery. They feature strong construction to withstand river currents and frequent mining operations. River sluice boxes are usually made of durable aluminum or HDPE plastics, ensuring that they won't easily break or become deformed during use. This means that miners can use them for a longer time. Using a river sluice box can also make the gold mining process cheaper because fewer materials are needed for mining.

Gold Grabber Sluice:

Gold Grabber Sluices are powerful gold recovery machines with high extraction rates. They are made to capture gold more effectively than other regular sluice boxes. The special design of Gold Grabber Sluice minimizes the chances of losing even the tiniest gold bits. Gold Grabber Sluices are still portable, making them ideal for small-scale or recreational gold mining.

Vortex Sluice:

The vortex sluice box is a modern and effective option for gold prospectors. It replaces the traditional riffles with vortex traps. These traps create swirling eddies that securely hold the gold particles, significantly reducing the chances of gold loss. Vortex sluice boxes are easy to clean, making them a popular choice among serious gold hunters.

Highbankers:

A highbanker sluice box is a piece of equipment used by gold miners to separate gold from dirt. Gold miners shovel dirt into the highbanker, where water and machinery help to find the gold. Highbankers can be thought of as advanced sluice boxes with added features and technology to improve gold recovery. Highbankers have pumps or engines that provide the water flow for the separation process. Some models even have screens to sift the dirt better. When using a highbanker, it's important to keep the area around it clean and not let contaminated water run back into rivers or lakes. To do this, miners can set up a pond or filtration system to catch any dirt or chemicals in the water before they throw it away.

Sluice boxes for gold mining come in different sizes to suit the needs of miners. Here are some general specifications regarding their dimensions, weight, and material.

The main maintenance task required for a sluice box is cleaning it after use. Doing this regularly will prevent the accumulation of dirt and debris, and the box will remain in good condition. Follow these tips to clean a sluice box mining tool:

Apart from gold mining, sluice boxes are also used in the mining industry for other purposes.

When choosing a sluice box for mining or purchasing them for resale, certain factors must be considered to ensure the final product will satisfy customers' needs. The primary factors to consider when choosing a mining sluice box are its size, material, design features, and its ability to work with a specific type of detector or the water flow characteristics of a particular location.

Size

The length and width of the mining sluice box should be considered. Length is important because longer sluice boxes offer more space for separation, which can process larger amounts of material but may require more water and a higher flow rate. Width is important in that wider sluice boxes prevent material from flushing out the bottom and allow more rapid separation of gems and gold.

Material

The sluice box's construction material will also be an important selling point, even though it may be more important to the end user's requirements. Aluminium has the advantage of being lightweight, enabling easy portability, while wood has the advantage of better material segregation. Plastic sluice boxes are affordable and lightweight.

Design features

Consider other design features of the sluice box, such as the type of riffles and the drop from the top to the bottom end of the box. Combo riffles offer miners better separation efficiency, while the gradual drop enables the natural settling of materials within the box.

Compatibility with detectors

Some mining locations have specific sets of conditions that require particular types of machinery to mine efficiently. Compatibility with other items a prospector or miner has is essential. For example, buyers may want to look for sluice boxes compatible with a gold detector to increase gold-catching efficiency in specific locations.

Knowing what customers seek is crucial to stock up on mining sluice boxes that accommodation most miners/customers. Consider the factors above when purchasing mining sluice boxes for resale to ensure they are suitable for end users. If unsure, it's best to sample a few variants to see what is ideal for most miners.

Q1. How are sluice boxes used today?

A1. Modern sluice boxes are still used in small-scale gold mining but are made of plastic or aluminum instead of heavy materials like wood or metal that were used in previous generations.

Q2. What are the limitations of sluice boxes?

A2. The main limitation of a well-designed sluice box is that it can only separate out a few minerals at a time, so even though the recovery rate of valuable minerals is high, it is still possible to leave a lot of them behind.

Q3. What is the principle of a sluice box?

A3. The basic principle of the sluice box is to use the difference in specific gravity and shape between gravel and gold to separate them.

Q4. What are the benefits of a sluice box?

A4. The sluice box has several advantages. First, it is easy to make, and both gold miners and amateur prospectors can manufacture it themselves. Second, the sluice box does not need electricity or any other fuel to work, and all it needs is running water. Third, the sluice box separates the gold very rapidly and is therefore used as a preliminary concentrator in many large mining operations.