The papad making machine is an advanced apparatus crafted to enhance the efficiency of papad production, a delectable crisp flatbread savored across various culinary traditions. This machine is adept at meeting the demands of food shops, hospitality establishments, home-based enterprises, and industrial manufacturers, facilitating a smooth shift from manual to mechanized papad creation. Prioritizing productivity and quality, the papad machine stands as an indispensable tool for entities aiming to expand their operations.

Types of Papad Making Machines

An array of papad making machines exists, each customized for specific production requisites. Ranging from mini papad making machines suited for modest ventures to fully automatic papad machines for extensive commercial output, the selection is broad. Certain machines are fine-tuned for specific papad varieties, such as the khichiya papad machine, which is adept at managing the fragile nature of khichiya papads. The papad banane ki machine price fluctuates based on capacity and functionalities, presenting options for enterprises of every scale.

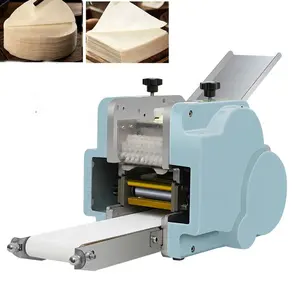

Structure and Operation of Papad Making Machines

The papad making machine consists of several integral components that synchronize effectively. Key elements encompass a dough mixer, a sheeter to roll the dough into thin layers, a cutter or molder for shaping the papads, and a drying conveyor to eliminate moisture. Each part plays a pivotal role; the mixer ensures uniform dough, the sheeter attains the requisite thinness, the cutter yields consistent shapes, and the conveyor meticulously dries the papads. This symphony of components enables a streamlined and proficient process, yielding top-notch papads with reduced manual input.

Materials Used in Papad Making Machines

The construction materials for a papad making machine are chosen for their robustness, cleanliness, and operational efficiency. Predominantly crafted from 304 stainless steel, these machines are resistant to corrosion and simple to clean, which is vital for food processing. The utilization of stainless steel also guarantees enduring performance under constant use, without compromising the papads' integrity.

Business Usages and Applications

The papad making machine is versatile across different commercial environments. In food shops, it boosts papad production efficiency, ensuring a more immediate availability of the product. Hotels employ it to effortlessly cater to large gatherings, while manufacturing plants mass-produce papads for retail. Each context benefits from the machine's consistent output, which aids in preserving brand reputation and consumer contentment. The machine's adaptability also permits the crafting of related items, such as tortillas and chapatis, thus broadening a business's product range with a singular investment.

Functions of Papad Making Machines

The chief role of a papad making machine is to mechanize the papad production process. It undertakes tasks like blending ingredients, rolling dough to exact thicknesses, shaping the dough, and drying the papads to an optimal moisture level. This mechanization not only escalates production volume but also guarantees uniformity in each papad, which is essential for customer satisfaction and brand uniformity.

Features of Papad Making Machines

The automatic papad making machine boasts a suite of features that distinguish it from its competitors. Its precision in production, energy-efficient design, and subdued noise operation are among its key selling points. The machine's intuitive interface and components that are easy to clean also stand out, diminishing the time and labor required for its operation and upkeep.

Benefits of Using Papad Making Machines

Enterprises reap multiple advantages from the papad making machine. The mechanization of papad production slashes labor expenses and curtails waste, while the uniformity in product quality can foster enhanced customer loyalty. The machine's rapidity and efficiency also empower businesses to satisfy elevated demand without compromising on quality, offering a market advantage.

How to Use the Papad Making Machine

Effective operation of a papad making machine involves configuring the apparatus as per the manufacturer's guidelines, selecting the preferred thickness and shape, and then introducing the dough into the machine. The machine then assumes control, rolling, cutting, and drying the papads. Consistent monitoring is advised to ensure the excellence of the end product.

How to Choose the Right Papad Making Machine

Selecting an appropriate papad making machine hinges on production requirements, spatial constraints, and fiscal considerations. Businesses should weigh the machine's throughput, compatibility with extant kitchen apparatus, and the assortment of papads it can fabricate. The extent of post-purchase support provided by the manufacturer is also a critical factor.

How to Clean and Maintain the Papad Making Machine

Cleaning and upkeep of a papad making machine entail disassembling detachable parts for sanitation, sterilizing food-contact surfaces, and adhering to a regular maintenance regimen to preserve the machine's longevity and performance. Utilizing the recommended cleaning solutions and lubricants is crucial to avert damage to the apparatus.

How to Install the Papad Making Machine

Installation of a papad making machine should be executed by a qualified technician or in accordance with the manufacturer's directives. Proper setup is essential for the machine's accurate and safe operation. Typically, this involves assembling the main unit, connecting power sources, and adjusting settings to suit the specific papad production needs.

Target Audience and Meeting Needs

The intended market for papad making machines spans small to large food enterprises, entrepreneurs venturing into the food production sector, and established producers seeking to enhance their output capabilities. The machine addresses the needs of this varied clientele by providing scalable solutions that can evolve with the business, ensuring that an investment in a papad making machine is beneficial at every stage of business development.

How does the papad making machine ensure product quality?

Whether for small or large operations, the papad making machine for small business is conceived with a focus on quality. From the initial ingredient introduction to the final product, the machine maintains stringent oversight over each production phase. The meticulous engineering of its components guarantees papads' consistency in size and thickness, while the stainless steel build prevents contamination, complying with food safety standards.

What are the key considerations when choosing a papad making machine?

In selecting the ideal papad banana machine, several aspects must be considered. The production volume, dimensions of the machine, and energy requirements should match the operational needs of the business. The machine's ability to integrate with current kitchen infrastructure and its versatility in producing a range of flatbreads are also significant. Additionally, the manufacturer's after-sales service level is an important consideration for potential buyers.

How to maintain and clean the papad making machine?

Maintaining and cleaning the mini papad making machine is facilitated by its design for ease of sanitation. Adherence to regular cleaning protocols is essential to meet hygiene standards. Parts in direct contact with food should be removed and cleaned separately to prevent microbial accumulation. Following the manufacturer's maintenance instructions will extend the machine's service life and ensure its reliability in the production line.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4