(11669 products available)

Ready to Ship

Ready to Ship

Using a PCB CNC machine, people can make products like smartphones, tablets, and other electronic gadgets. What sets this machine apart is its ability to manage complicated technical configurations while keeping costs reasonable compared to manual procedures.

Key types of pcb cnc machines:

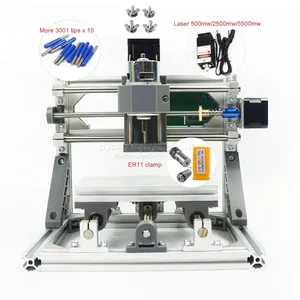

pcb milling machine

A CNC machine for PCB engraving is a popular type of PCB CNC machine. The milling cutters will engrave the PCB and remove the copper layer to create a copper trace on the PCB. The CNC machine for PCB milling can accomplish a great deal by itself. No further tools are required to make the PCB layouts. This device can drill, cut, and engrave all at once, which makes it very helpful in the space-saving industry.

pcb depaneling machine

This is a laser-based PCB depaneling machine. A guide plate or laser beam is used to illustrate the cutting postures of the blades. The perfect alignment of the blades with the PCB is made possible by this approach, ensuring effective and precise cutting. Low-cost laser depaneling devices work best for cutting PCBs into separate units. Their main purpose is to provide a low-CNC solution to quickly and easily kmake prototype PCBs. These devices have affordable running expenses, low-labor requirements, and quick turn-around times.

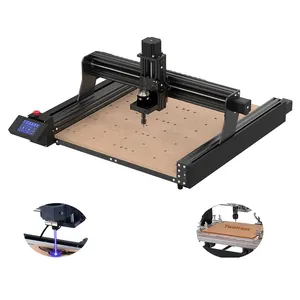

The main specifications when buying a PCB CNC machine for sale are the type and size of the machine, the structure and table, the spindle and motor, the software, and the power supply.

Becauseof the variety of PCBs, many different types and sizes of CNC machines exist. As shown above, some are designed especially for small to medium-sized PCBs, such as the table-top varieties with a work area of 300 x 200 mm or more. Others are more extensive and suit larger boards, such as the models with a work area of 1,200 x 1,200 mm and over, which look more like a whole cabinet or larger unit.

The machine's structure and table provide stability during the cutting process. Generally, the base is made out of a sturdy material like cast iron, which offers good shock absorption and stability. The tabletop is made out of a flat aluminum alloy and is often coated to be anti-corrosive, anti-skid, and more durable.

The spindle and motor will drive the cutting drill bits, which do the circuit cutting. The driving motor moves the PCB around. These parts usually come in a variety of sizes to meet different needs, but a stronger torque motor is preferred in machinery that cuts hard materials.

The software will usually guide the whole process of designing the PCB layout and controlling the precise cutting. The software provides a user-friendly interface for design input, and the machine will accurately cut based on computer-aided design files.

A PCB CNC machine usually needs a standard power supply of about 450W to 600W for it to work thoroughly and reliably. Ensure the input voltage is between the specified ranges.

To keep the machine working well, it is necessary to clean it regularly to remove any used drill bits, dust, or other residue. This prevents build-up or blocking of any moving parts. One should also get rid of any debris to keep the working area safe, as loose items or parts may pose a risk of causing injury or damaging the board. Further, the machine should be lubricated with a standard use lubricant to help all the moving parts run smoothly and reduce wear and tear. Regular inspection of the machine parts is necessary to keep them working at optimal levels, and it is good to look for signs of damage or areas needing repair or replacement. Finally, buyers should consult the user manual for specific maintenance details related to the model they have purchased.

PCB Prototyping:

In the electronics design industry, engineers frequently need to fabricate prototypes of PCB designs to validate them physically. A PCB CNC machine empowers them to swiftly and precisely create prototypes. This capability allows for a quick iteration of the design, reducing the time required for testing and validation phases. As a result, the final product is optimized, and potential issues are addressed early in the process.

Small-scale Production:

For startups and small businesses in the electronics field, a PCB CNC machine presents an economical solution for small-scale PCB production. Instead of outsourcing the manufacturing process—which can be expensive and time-consuming—they can produce their own PCBs in-house. This not only lowers production costs but also increases control over the manufacturing process, enhancing efficiency and responsiveness to market demands.

Educational Purposes:

In the educational sector, particularly within universities and vocational training centers, a PCB CNC machine proves invaluable for teaching purposes. Students can use the machine to gain practical experience in PCB fabrication, thereby deepening their understanding of PCB design software and CNC machining techniques. This hands-on learning fosters student engagement and equips them with essential skills required for future employment in related fields.

Repair and Modifications:

In the electronics repair industry, a PCB CNC machine facilitates the repair and modification of existing PCBs. This is particularly useful in scenarios where original PCB designs are no longer available or where small alterations are needed. The CNC machine enables technicians to make precise changes swiftly and accurately, thereby accelerating the repair process and minimizing downtime for the customer.

Rapid Prototyping Service:

For companies offering rapid prototyping services, investing in a PCB CNC machine can significantly enhance their service offering. The machine allows them to produce PCBs quickly and efficiently, meeting the fast turnaround times expected by customers in various industries. By incorporating PCB CNC capabilities into their service portfolio, these companies can attract and retain more customers, thus driving business growth and success.

Production volume:

Specification requirements:

Ease of use:

Budget:

Support and service:

Q1: Can a CNC machine make a PCB?

A1: Yes, a CNC machine can be used to make a PCB. CNC machines are capable of performing various tasks such as milling, drilling, and engraving the copper layer on the circuit board.CNC machines are used to create proto PCBs for electronic devices, mobile phones, and other technology components.

Q2: What material does a CNC PCB use?

A2: The most common materials for CNC PCBs are FR-4, PTFE, and ceramics. FR4 is woven glass epoxy resin, which has great electrical insulation properties. PTFE, also known as Teflon, is good for high-frequency circuits because it has a low dielectric constant. Ceramic offers great stability and can withstand high temperatures and is mostly used in high-performance circuits.

Q3: What are the advantages of using a CNC machine for PCB manufacturing?

A3: There are many benefits of using a CNC machine to make PCBs. One of them is faster production, as multiple boards can be made within a short time. The precision and accuracy of the machine ensure that the boards are of good quality. Lastly, the machine offers flexibility, enabling it to create different types of designs.