(5812 products available)

Ready to Ship

Ready to Ship

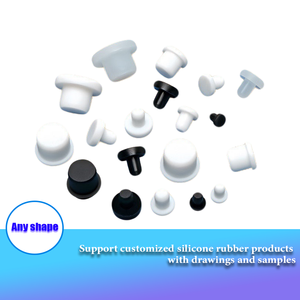

Small rubber caps come in various shapes and types to meet specific needs. They are mostly used in the automotive and electronics industries and known as dust caps, end caps, tube plugs, and bottle stoppers.

Rubber caps function better when they match or complement the internal or external profile they cover. For instance, cylindrical caps cover cylindrical structures like pipes and bars. Dome caps shield components like screws with a rounded end. Conical caps protect parts that taper. Custom shapes are also made to order for specific parts.

Rubber caps can also be classified according to whether they are meant to protect an internal part versus an external one. Internal rubber caps are designed to fit snugly inside components, such as sockets, to shield them from damage. These caps serve as protective barriers, preventing external factors from compromising the integrity of internal parts.

Conversely, external rubber caps are used to cover external features, such as bolts or rods. These caps are often molded onto permanent components and are more visible.

The dimension diversity of these caps is in their functionality. Stainless steel caps that are tiny can be made to fit metric screwthreads of M1 sizes or fine 1/20 inch U.N.C. screws through caps that range 0.1 inch to 0.75 inch external diameter. Larger sizes of caps that can be up to 2 inches of diameter or above incorporate protective dust caps where such requirements are necessary.

Plastic bottle caps are manufactured in a variey of materials to provide varying degrees of elasticity, resistance to temperature, and mechanical strength. They are made of rubbery thermoplastics, including thermoplastic elastomer, natural rubber, and silicone.

Silicone screw caps for bottles are silicone and provide good retention under extreme temperatures. This is why silicone is widely used in applications within the automotive and aerospace domains that are exposed to high heat. Silicone's flexibility also causes it to create an ideal sealing.

Nitrile rubber is popularly used to manufacture caps for bottles and comes handy in resisting oils and chemical solvents. Nitrile rubber is also widely used and valued by its compressive strength and durability in providing protection against puncturing and tearing.

Ethylene propylene diene monomer (EPDM) rubber is used in caps for outdoor applications. This is because EPDM is resistant to ozone, UV radiation, and atmospheric oxygen. These cap materials last over a decade under continuous outdoor exposure, making them excellent for long-term durability.

These materials are selected for their specific advantages based on the operating environment and desired performance features.

Starting a rubber bottle cap business requires a close focus on market demand and the competition. Therefore, one must do research to provide information on what to do to increase sales to understand better what customers need and popular products. Some other things to consider are:

The business cost of launching a small rubber cap venture is determined mainly by the chosen materials, production processes, and whether manufacturing or purchasing inventory. Operating expenses such as marketing and staffing are other aspects affecting the overall cost. These expenses should be well understood since they influence pricing and profitability decisions.

The type of material selected directly influences the quality and application of caps. For instance, silicone caps are very suitable for applications requiring resistance to temperatures. Nitrile caps are typically used where chemicals are involved, while EPDM caps find widespread use in outdoor applications.

The amount of stock or inventory that will be held depends on how large the business is intending to be. When the volume is known, decisions such as whether to offer various sizes and materials stocked or a range of different types stocked are easier to make.

Rubber caps are highly valued in commercial setup due to their very diverse applications and ability to provide protection. Their usefulness in shielding electronic components, automotive parts, and precision engineering items from damage is the main reason for this high valuation.

The above means that plastic bottle caps are an essential requirement in the electronic element industry, where they protect microcircuitry and connectors from moisture and debris. In this industry, their small size means they can conceivably protect the smallest component. For the automotive industry, these products protect engine components and vehicle parts. For precision engineering, they are used to cap delicate machinery.

This versatility means that rubber caps are in demand across the board in various industries.

Rubber caps can be inexpensive, and an easy solution to replace often contributes to their commercial popularity. What this means is that considering the protective silicone lid for male contraceptive spermicide components used in products that are risk exposed will not cost much. In fact, even dust caps that won’t protect but prolong the lifespan of components is considered by many users. The rubber caps are pleasantly spoilt with diverse colors, shapes, and prints. This makes them a weapon not only for functionality but also for branding purposes.

Small rubber caps are used in the electronics, automotive, and engineering industries. Less widely used in these industries, the dust caps are used to protect electronics like microcircuitry and connectors. And since there is an increasing trend in these industries, there is a high chance that rubber caps demand and value will increase in the coming years.

The following points should be noted when purchasing these items for business use.

It is worth noting that there are different types of bottle caps. These include screw caps, cork caps, safety caps, sport caps, and swingtop caps, among others. Each of these cap types serves a different type of container.

Rubber caps should be compatible with the bottle or container they are intended for. Consider the size and shape of the container's opening to ensure a proper fit. This ensures a tight seal and effective protection.

Compare the cap's sealing mechanism features with the requirements for sealing by targeted products. Certain caps have internal liners for extra sealing. One may also consider adjustable or interchangeable caps for versatile rubber caps, which are catalogued and frequently used for various containers.

There are various attachments available to different suppliers, each with its own benefit and characteristics. One should look for a reputable supplier who can offer quality caps at competitive prices. Read other customers' reviews and ratings to understand better the supplier's quality and service.

A1: Small rubber caps protect various items like tools, plumbing parts, and electronic devices. They act as covers or shields, keeping things safe from damage, dust, and moisture.

A2: Yes, small rubber caps are made to be tough and long-lasting. They are designed to protect items outdoors because they resist wear and damage. These rubber caps are tough and versatile.

A3: Yes, small rubber caps are ideal for outdoor and indoor applications. Weather-resistant EPDM rubber caps are preferred for outdoor use because they can withstand UV exposure, ozone, and environmental elements. They are suitable for outdoor applications by providing durable protection.

A4: While rubbers extend the lifespan of protected products, they are not needed. However, using caps is recommended. The cap protects products from damage, weather, and other elements. This keeps the product safe and in good working condition.

A5: Consumer can silicone, natural rubber, nitrile rubber, or EPDM rubber. Each material is suited for applications requiring flexibility, chemical resistance, or outdoor durability.