(510 products available)

A splined steering shaft, also known as a steering column, is an important component of the car's steering system, and it connects the steering wheel to the steering gear. The shaft transfers the driver's input from the steering wheel to the wheels, enabling the car to change directions. There are various types of splined steering shafts, including:

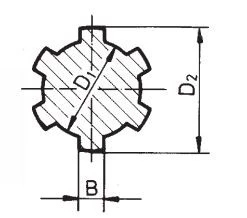

When selecting a 36 spline steering shaft for a specific application, several specifications need to be considered. Here are some of the key specifications:

Like any other mechanical part, the steering column spline requires maintenance to ensure optimal functionality and prevent breakdowns. Below are some maintenance tips for the splined shaft:

When sourcing for splined steering shafts, it is important to consider several factors in order to obtain good performance and compatibility in vehicles. Here are some of the factors to consider:

When choosing a splined steering shaft, it is important to consider vehicle specifications. This includes the make, model, and year of the vehicle. Also, one should consider the type of vehicle, whether it is a car, truck, or SUV. This information is important as it helps to ensure that the 9 16 26 spline steering shaft selected is compatible with the vehicle. Therefore, it will fit perfectly and work effectively, enhancing the performance of the steering system.

When choosing a splined steering shaft, it is important to consider the shaft material. Splined steering shafts are available in different materials, each having its own benefits. For example, steel is strong and durable, while aluminum is lightweight. Therefore, one should select a shaft material that is strong, durable, and suitable for the needs of the vehicle.

One should also consider the size of the splined steering shaft when choosing a splined steering shaft. This includes the length and diameter of the shaft. The size of the shaft is important as it helps to ensure that the splined steering shaft selected is compatible with the vehicle's steering system. Therefore, it will fit perfectly and work effectively, enhancing the performance of the steering system.

When choosing a splined steering shaft, it is important to consider the input and output options. This includes the type of connection at the input and output ends of the shaft. For instance, keyways, universal joints, or flanges. This information is important as it helps to ensure that the splined steering shaft selected is compatible with the vehicle's steering components. Therefore, it will fit perfectly and work effectively, enhancing the performance of the steering system.

When choosing a splined steering shaft, it is important to consider the quality and brand. It is advisable to source products from reputable manufacturers. This is because reputable brands have a good reputation for producing high-quality and durable products. Additionally, one should read customer reviews and testimonials to get an idea of the quality of the brand's products.

While it's always recommended to get a professional mechanic to change a spline steering shaft, it’s also possible to do it as a DIY project. Below are the step-by-step instructions on how to replace a splined steering shaft.

Tools and materials

Step 1: Disconnect the battery

It is important to disconnect the battery before doing any work on the steering wheel to prevent any accidents. Use a wrench or a socket set to disconnect the battery.

Step 2: Remove the steering wheel

Use a steering wheel puller to remove the steering wheel. The steering wheel puller will release the steering wheel from the spline shaft. By so doing, the puller will also prevent damage to the steering shaft.

Step 3: Remove the lower dash panel

Remove the lower dash panel to access the universal joint connection. Use a screwdriver to unscrew the bolts and remove the lower dash panel.

Step 4: Disconnect the universal joint

Disconnect the universal joint by unbolting it from the steering column and the rack-and-pinion. Then, slide the universal joint off the splined shaft.

Step 5: Remove the old splined steering shaft

Use a wrench or a socket set to remove the bolts that secure the old splined steering shaft. Remove the old shaft from the vehicle.

Step 6: Install the new splined steering shaft

Insert the new shaft into the steering column. Then, tighten the bolts to secure the shaft.

Step 7: Reconnect the universal joint

Slide the universal joint onto the new shaft and then bolt it to the steering column and rack-and-pinion.

Step 8: Reinstall the lower dash panel

Reinstall the lower dash panel and ensure that it is properly secured.

Step 9: Reinstall the steering wheel

Reinstall the steering wheel and ensure that it is properly aligned with the vehicle's wheels.

Step 10: Reconnect the battery

Reconnect the battery once the steering shaft is successfully installed and tested.

Q1: What is the importance of the splined shaft?

A1: The splined shaft is important for transmitting power from the engine to the wheels. It provides a connection between the steering wheel and the steering gear, allowing the driver to control the direction of the vehicle. This is a crucial component of the vehicle's steering system.

Q2: Can the splined steering shaft be repaired?

A2: In some cases, the splined steering shaft can be repaired if it is damaged or worn out. However, the repair process requires special tools and expertise. It is recommended to consult a professional mechanic to assess the condition of the shaft and determine if it can be repaired.

Q3: What are the common problems of the splined steering shaft?

A3: The common problems of the splined steering shaft include wear and tear, corrosion, misalignment, and inadequate lubrication. These issues can result in difficulty steering, strange noises, and movement in the steering column. The driver should inspect the shaft regularly to detect the problems at an early stage.

Q4: Can the splined steering shaft be upgraded?

A4: Yes, the splined steering shaft can be upgraded to improve its performance and durability. There are many aftermarket options available for different vehicle models. The driver should ensure that the upgraded shaft is compatible with the vehicle's steering system.

The web search volume for the keyword "splined steering shaft" in the Vehicle Parts & Accessories category shows an average monthly web search volume of 70. Over the past year, there has been a consistent decline of 29% in web search volume. The data from the last twelve months reveals fluctuations, with peaks reaching 90 web searches in January and May, and valleys dipping to 50 web searches in April and November.

Analyzing the trend in more detail, the web search volume for "splined steering shaft" experienced its highest spikes in January and May, possibly influenced by seasonal demand or specific market events during those months. Conversely, the lowest points in April and November suggest a reduced interest or potential market saturation at those times. Throughout the year, the web search volume generally hovered around the 70 mark, with occasional deviations.

This trend of a 29% decrease over the year could imply a gradual shift in market dynamics or a change in consumer preferences. The peaks and valleys observed throughout the year might correlate with automotive repair cycles or seasonal vehicle replacements, where parts like the splined steering shaft become more in demand during specific periods. Understanding these patterns helps manufacturers and retailers anticipate demand and plan inventory accordingly.